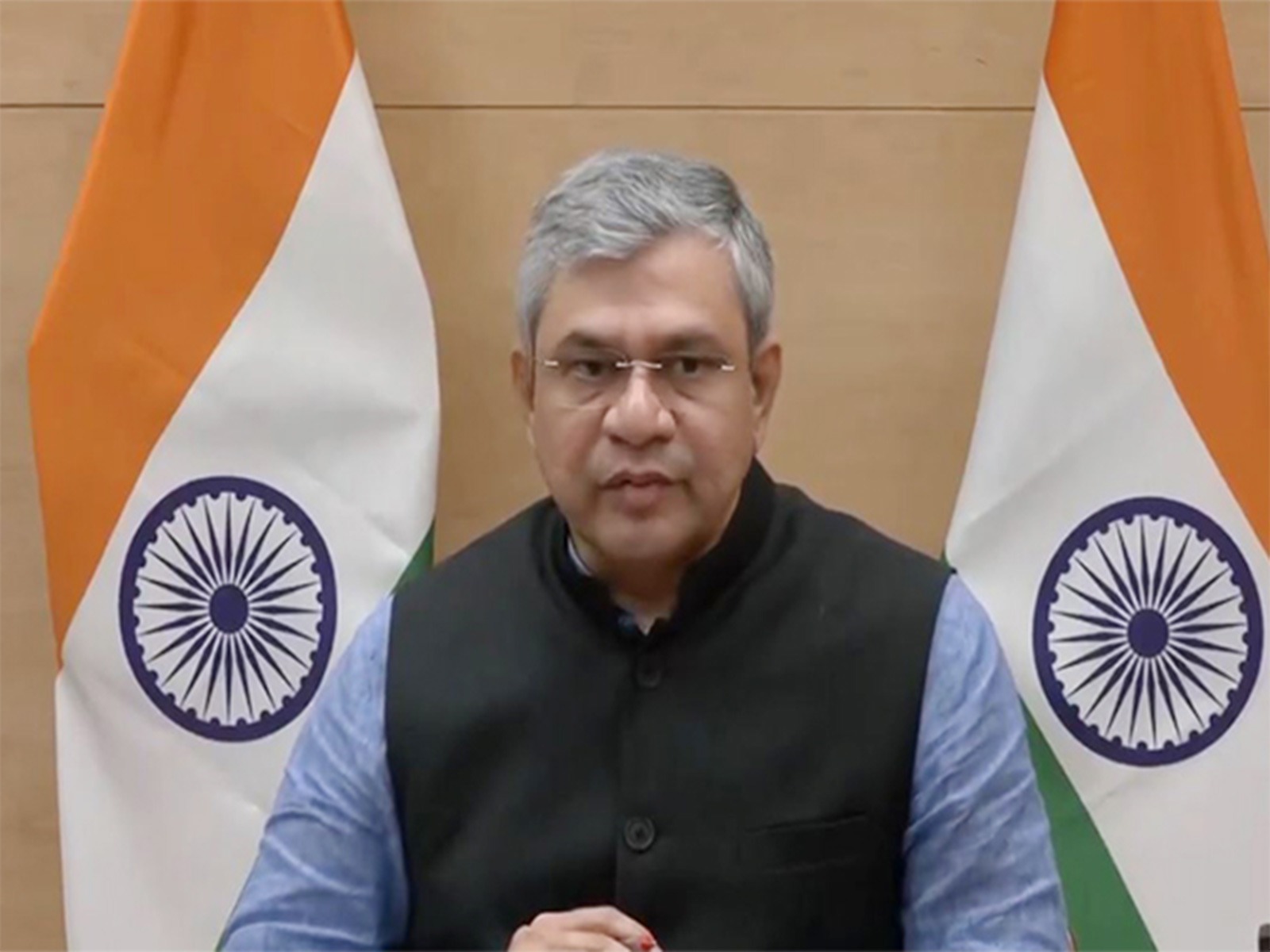

Railways Minister announces second mountain tunnel in Palghar for Bullet train project

Feb 03, 2026

New Delhi, [India] February 3 : Railways Minister Ashwini Vaishnaw on Tuesday announced a significant milestone in the Bullet Train Project with the breakthrough of the second mountain tunnel in Maharashtra's Palghar.

This tunnel is 454 metres long with a width of 14.4 metres, and will accommodate both up and down tracks for the Mumbai-Ahmedabad Bullet Train project, according to an official release issued by the Ministry of Railways.

This is the second mountain tunnel breakthrough in Palghar district within a span of one month for the Bullet Train project, the first being MT-5 near Saphale on January 2.

Minister Vaishnaw congratulated the entire high-speed rail team for their remarkable progress.

He said the pace at which the team is working has instilled new confidence in the country. "The project is drawing global attention and appreciation due to several new innovations in construction and technology. He highlighted that many advanced construction technologies and large machines being used for the project are manufactured in India," he said.

The minister stated that the Gujarat section of the bullet train project is expected to begin commercial operations next year. He added that high-speed rail operations are expected to extend up to Thane by 2028, with the corridor reaching Mumbai by 2029.

As per the Railways Ministry, the mountain tunnel (MT-6) was excavated from both ends using the New Austrian Tunnelling Method (NATM), a cutting-edge drill-and-controlled blast method. The excavation is completed within 12 months.

A mountain tunnel breakthrough marks a key engineering milestone when excavation teams digging from opposite ends of the tunnel finally meet at the centre, forming a continuous passage through the mountain.

The New Austrian Tunnelling Method (NATM) is favoured for its flexibility in complex geological conditions, such as in the Palghar district and irregular tunnel shapes, where tunnel boring machines are not suitable. This process does not require very heavy machinery and allows real-time adaptation using shotcreting, rock bolts and lattice girders.