Semiconductor mission pushes India from being aspirant to becoming global powerhouse

Aug 03, 2025

New Delhi [India], August 3 : India is undergoing a transformative journey in the semiconductor space, rapidly building an ecosystem that promises to position the country as a major hub in the global chip manufacturing and design value chain.

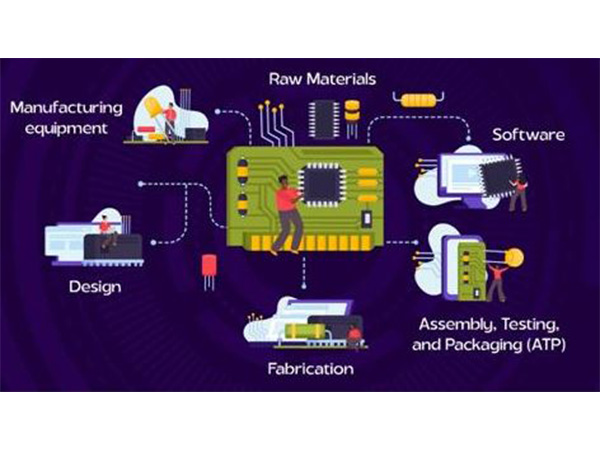

What makes a phone smart? A computer processes millions of commands in a fraction of a second. A TV brings out the reality as it is happening right now. A satellite collects data and sends signals across the world. It all comes down to that tiny thing called a semiconductor chip, which one can hold between one's fingers.

With the global chip market expected to surpass USD 1 trillion by 2030, India is not only aiming to reduce its dependence on imports but also to emerge as a trusted partner in the diversified global supply chain, PIB shared as part of its backgrounder series.

At the heart of this transformation is the India Semiconductor Mission (ISM), launched in December 2021 with an outlay of Rs 76,000 crore.

The mission is aimed at fostering chip manufacturing, packaging, testing, and design capabilities. It also promotes collaboration between academia and industry to boost R&D and develop a highly skilled talent pool.

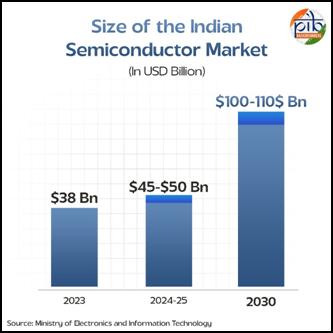

As per industry estimates, India's chip market stood at approximately USD 38 billion in 2023 and is projected to grow to USD 100-110 billion by 2030.

This growth is underpinned by a strategic policy push from the government, which includes several fiscal incentive schemes. Under the Semiconductor Fabs Scheme, companies receive up to 50 per cent financial support for setting up semiconductor fabrication plants.

Similar schemes support display manufacturing, packaging units (ATMP/OSAT), and design startups through the Design Linked Incentive (DLI) scheme.

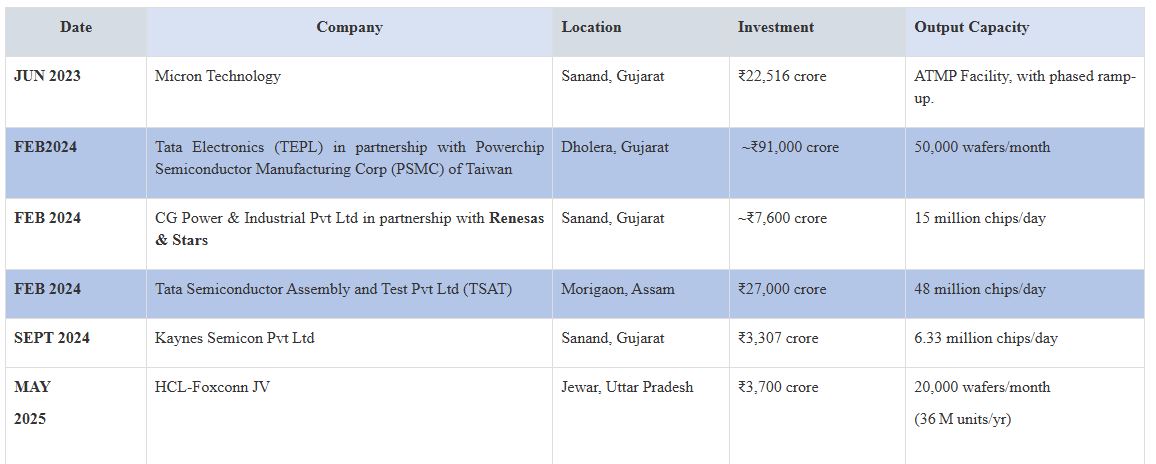

By far, six major semiconductor projects have been approved. These include multi-billion-dollar investments from Tata Group, Micron Technology, CG Power, Kaynes Semicon, and an HCL-Foxconn joint venture.

Together, these units will collectively produce millions of chips and wafers per month, fulfilling both growing domestic and global demand.

India's design ecosystem is also seeing rapid growth. The recent inauguration of 3-nanometer chip design centres in Noida and Bengaluru marked a breakthrough in high-end chip innovation.

To encourage this trend, the DLI scheme has supported as many as 22 startups with Rs 234 crore in funding. These companies are designing chips for critical applications such as CCTV surveillance, mobile networks, smart devices, and automotive systems.

Skill development is another key priority under the semiconductor mission. Over 85,000 engineers are being trained in advanced semiconductor and electronics manufacturing, with over 44,000 already certified under the SMART Lab initiative at NIELIT Calicut.

Partnerships with global institutions like Purdue University and industry leaders like IBM and Lam Research aim to align Indian talent with international standards.

India's growing ambition in semiconductors is showcased annually at the SEMICON India summit, the flagship event hosted in partnership with SEMI (Semiconductor Equipment and Materials International). The 2025 edition, set to take place at New Delhi's Yashobhoomi during September 2-4, will see over 300 exhibitors from 18 countries, including pavilions from Japan, South Korea, Singapore, and Malaysia.

With country roundtables, design startup showcases, and skilling forums, the event will highlight India's commitment to collaboration and innovation across the semiconductor value chain.

The geopolitical shocks of the COVID-19 pandemic and the Ukraine conflict exposed vulnerabilities in the global semiconductor supply chain, dominated by a few nations like Taiwan, South Korea, China, and the United States.

India's push for local manufacturing and design is both a strategic and economic response to reduce reliance on such concentrated geographies.

With abundant raw materials, a thriving MSME sector for component manufacturing, and a large base of engineers skilled in AI, IoT, and cloud computing, India is uniquely placed to contribute to the entire semiconductor lifecycle.

As approved facilities begin operations and new projects take shape, the country is positioning itself as a trusted hub for semiconductor manufacturing, strengthening its digital economy, national security, and technological self-reliance.

"From dependence to dominance, the chip revolution is real and its happening right here, right now in Bharat," the PIB essay concluded.